Tribupneu: Understanding the Concept Meaning and Emerging Relevance

Introduction to Tribupneu

Tribupneu is a term that has recently attracted attention across technical blogs, informational websites, and emerging industry discussions. While it may appear unfamiliar at first glance, the word itself provides valuable clues about its meaning and purpose. Tribupneu is generally understood as a conceptual fusion of tribology, the science of friction, wear, and lubrication, with pneumatic systems that rely on compressed air for motion, control, and power transmission. Together, these two disciplines form a framework aimed at improving efficiency, durability, and performance in air-driven mechanical and industrial systems.

The growing interest in Tribupneu reflects a broader shift toward optimizing mechanical processes while reducing energy loss and system degradation. As industries become more automation-driven and sustainability-focused, concepts like Tribupneu are increasingly relevant. Rather than being a single patented technology, Tribupneu is best described as an interdisciplinary approach or conceptual model that influences how pneumatic systems are designed, operated, and maintained.

The Meaning and Linguistic Roots of Tribupneu

The term Tribupneu is formed by combining two well-established scientific domains. “Tribu” is derived from tribology, a field that studies how surfaces interact when in relative motion. Tribology examines friction, wear, lubrication, and surface engineering, all of which play a critical role in mechanical efficiency and lifespan. “Pneu” originates from pneumatics, the branch of engineering that uses compressed gases, usually air, to generate motion or control systems.

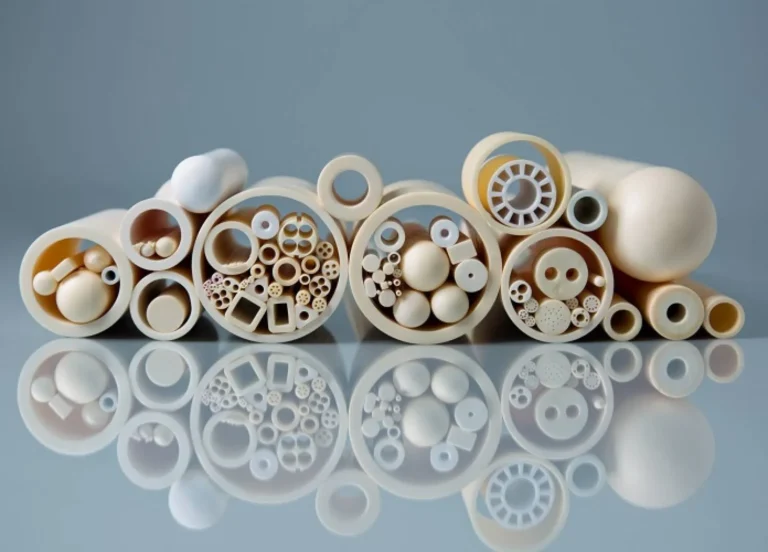

When these elements are combined, Tribupneu represents a holistic perspective that considers not only airflow and pressure control but also surface interactions inside pneumatic components. Valves, cylinders, seals, and actuators all involve moving surfaces, and tribological factors significantly influence their reliability. Tribupneu therefore emphasizes the importance of managing friction and wear within pneumatic environments.

Conceptual Foundation of Tribupneu

At its core, Tribupneu is built on the idea that pneumatic systems cannot achieve optimal performance without addressing tribological behavior. Traditional pneumatic engineering often prioritizes pressure levels, airflow rates, and mechanical design while treating friction and wear as secondary maintenance concerns. Tribupneu challenges this approach by integrating tribological analysis from the earliest design stages.

This conceptual framework recognizes that internal friction affects energy consumption, response time, and operational stability. By applying tribological principles such as advanced surface coatings, optimized lubrication strategies, and material compatibility analysis, pneumatic systems can operate more smoothly and predictably. Tribupneu thus acts as a bridge between mechanical science and fluid power engineering.

Tribupneu in Modern Industrial Contexts

In modern industrial environments, efficiency and reliability are no longer optional goals. Manufacturing plants, automation lines, and robotics systems depend heavily on pneumatic components for speed and precision. Tribupneu plays a role by highlighting how micro-level surface interactions can influence macro-level system outcomes.

For example, in high-cycle pneumatic actuators, even small reductions in friction can translate into significant energy savings over time. Tribupneu-inspired designs focus on minimizing internal resistance, reducing seal wear, and ensuring consistent performance under varying pressure conditions. This perspective aligns well with Industry 4.0 principles, where data-driven optimization and predictive maintenance are key priorities.

Relationship Between Tribupneu and Energy Efficiency

One of the strongest arguments for the relevance of Tribupneu is its connection to energy efficiency. Pneumatic systems are known for simplicity and cleanliness, but they are also criticized for energy losses due to compression inefficiencies and frictional resistance. Tribupneu addresses the latter by reducing mechanical losses inside pneumatic components.

Lower friction means less energy is required to initiate and sustain motion. Over extended operational periods, this reduction can have a measurable impact on energy consumption and operational costs. In industries where compressed air represents a significant portion of energy expenditure, Tribupneu-oriented strategies can support both economic and environmental objectives.

Tribupneu and System Durability

Wear is one of the most common causes of pneumatic system failure. Seals degrade, surfaces erode, and components lose tolerance over time. Tribupneu emphasizes proactive wear management by applying tribological insights to material selection and surface engineering.

By understanding how different materials behave under pneumatic conditions, engineers can design components that resist abrasion and fatigue. Surface treatments, coatings, and lubrication methods become integral design elements rather than afterthoughts. Tribupneu thus contributes to longer service life, reduced downtime, and improved system reliability.

Applications of Tribupneu in Automation

Automation systems rely heavily on precise and repeatable motion. Tribupneu contributes to this precision by reducing variability caused by frictional changes and wear progression. In automated assembly lines, consistent actuator performance is essential for maintaining quality standards and production speed.

Tribupneu-based approaches support smoother motion profiles and faster response times. Reduced friction allows actuators to react more accurately to control signals, enhancing synchronization between mechanical and electronic systems. This integration is especially important in robotics, where even minor performance deviations can affect accuracy.

Tribupneu in Research and Development

Beyond immediate industrial use, Tribupneu is gaining relevance in research and development contexts. Engineers and material scientists explore how new surface technologies, such as nano-coatings and advanced polymers, interact with pneumatic environments. Tribupneu serves as a conceptual umbrella under which these investigations are organized.

Research inspired by Tribupneu often focuses on experimental validation of friction-reduction techniques and wear-resistant materials. These studies contribute to the broader knowledge base of mechanical engineering while offering practical insights for industrial implementation.

Tribupneu and Predictive Maintenance

Maintenance strategies are evolving from reactive to predictive models. Tribupneu aligns well with this shift by emphasizing the measurable impact of friction and wear on system performance. Sensors and monitoring tools can track changes in pressure response, energy consumption, and motion smoothness, all of which may indicate tribological issues.

By interpreting these signals, maintenance teams can anticipate component degradation before failure occurs. Tribupneu therefore supports smarter maintenance planning, reduced unplanned downtime, and improved safety in industrial settings.

Challenges and Limitations of Tribupneu

While the concept of Tribupneu offers many advantages, it also faces challenges. Integrating tribological considerations into pneumatic design requires interdisciplinary expertise that may not always be available. Engineers must balance cost, complexity, and performance when implementing advanced materials or surface treatments.

Additionally, the benefits of Tribupneu are often long-term and cumulative, making them less immediately visible than traditional performance upgrades. Organizations must adopt a strategic perspective to fully realize the value of this approach.

Future Outlook for Tribupneu

The future of Tribupneu appears closely tied to technological progress in materials science, sensor technology, and digital engineering tools. As simulation software becomes more sophisticated, engineers can model tribological behavior within pneumatic systems more accurately. This capability will further integrate Tribupneu principles into standard design practices.

Sustainability trends also favor Tribupneu-based thinking. Reducing energy consumption, extending component lifespan, and minimizing waste are all aligned with global environmental goals. As awareness grows, Tribupneu may become a recognized framework within pneumatic engineering education and professional practice.

Tribupneu as an Informational and Educational Topic

From an informational perspective, Tribupneu has gained visibility because it represents a convergence of established scientific fields presented under a single conceptual label. This makes it attractive for educational content, technical discussions, and knowledge-sharing platforms.

As more writers and researchers explore the topic, Tribupneu content is likely to become more refined and standardized. Clear explanations, real-world examples, and case studies will help solidify its place within technical discourse.

Conclusion

Tribupneu is more than a buzzword; it is a meaningful conceptual approach that highlights the importance of friction and wear management within pneumatic systems. By integrating tribological principles into pneumatic engineering, Tribupneu supports efficiency, durability, and performance improvements across a wide range of applications.

As industries continue to demand smarter, cleaner, and more reliable systems, the ideas behind Tribupneu are likely to gain further relevance. Understanding this concept provides valuable insight into the future direction of mechanical and pneumatic innovation, making Tribupneu an important topic for engineers, researchers, and industry observers alike.